The Idaho Transportation Department’s Division of Aeronautics recently began re-using paint typically discarded by the agency’s testing laboratory for re-striping local airport runways.

[Above photo by the ITD]

ITD’s Central Laboratory provides testing services for all the agency’s districts for a variety of construction materials used to build state transportation infrastructure – including the paint used for highway markings and striping.

Craftsmen Justin Fort and now-retired Joe Fleck with ITD’s aeronautics division, along with ITD District 3 Foreman Jerry Richards, found out that Central Labs disposes of about 60 to 70 gallons of paint each year after testing.

While it costs ITD’s aeronautics division $20 to buy a gallon of paint, it costs Central Labs about $200 to dispose of a five-gallon bucket of paint after testing. Thus, it made financial sense for the laboratory to hand off excess paint to the aeronautics division instead of paying to dispose of it, ITD noted.

The division got in touch with Central Labs Senior Chemist Rachel Owens and decided to pick up and start using the paint to help maintain runway markings and striping at Idaho’s 32 backcountry airstrips; markings that requires a fresh coat of paint every five years.

By thinking outside the box, ITD’s Central labs and aeronautics division are saving the agency $4,520 a year by using paint that normally ends up as expensive trash.

“We have painted four airstrips this fall, all with sample or test paint from Central Labs,” noted Fort in statement. “We have been collecting and saving the test paint for over a year, until this August, when we got our new sprayer. It took only two hours to spray the markers and segment circles at each airstrip.”

Many state departments of transportation are involved in projects that reuse and/or recycle a variety of materials within the infrastructure projects they oversee.

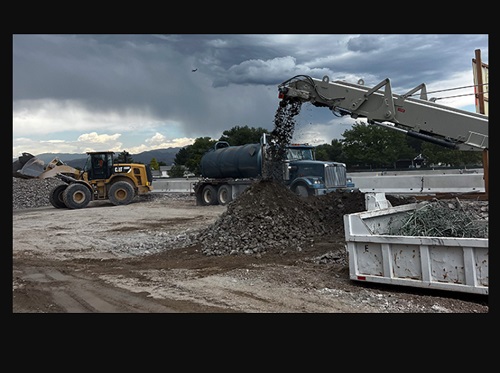

For example, the Utah Department of Transportation is recycling old concrete on the site of its Bangerter Highway project to help build the highway’s new interchanges.

To recycle concrete for reuse, the project’s construction crews use heavy machinery to break up the old sections of the highway, placing that material into an onsite crushing machine equipped with a large magnet inside to separate the concrete from the metal rebar, which is also recycled.

Once all the large cement chunks are crushed into tiny pieces, Utah DOT reprocesses the material into a road base for the new interchange.

In 2023, the New Jersey Department of Transportation released a video detailing how its use of “foamed glass aggregate” provides a multitude of green benefits to the state – especially as the material is made from recycled glass bottles.

Also in 2023, the “Q&A podcast” produced by AASHTO re:source – a technical service program offered by the American Association of State Highway and Transportation Officials – interviewed Ed Sniffen, director of the Hawaii Department of Transportation, for a two-part episode about how his agency has tested the incorporation of recycled plastics into its road paving processes.

Litter

Litter