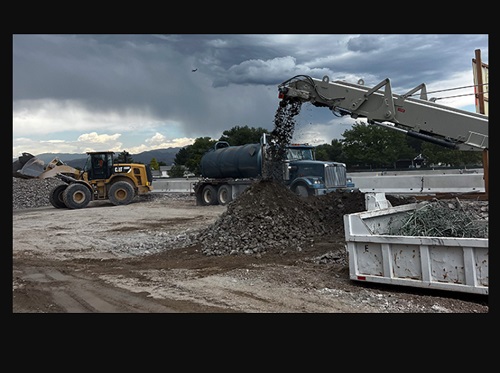

The Utah Department of Transportation is recycling old concrete on the site of its Bangerter Highway project to help build the highway’s new interchanges.

[Above photo by Utah DOT]

“In the past all of this concrete would have gone to waste and now is being recycled and reused for other projects,” noted Robert Stewart, director of Utah DOT’s Region 2, in a statement. “This pavement has been here for 30 years and it’s a great to be able to give it new life.”

He noted that construction crews have been working every day for the past five months on the recycling process, with Utah DOT opting to recycle the material on site instead of hauling off the material to another location to reduce the number of truck trips in the area.

To recycle concrete for reuse, the project’s construction crews use heavy machinery to break up the old sections of the highway, placing that material into an onsite crushing machine equipped with a large magnet inside to separate the concrete from the metal rebar, which is also recycled.

Once all the large cement chunks are crushed into tiny pieces, Utah DOT reprocesses the material into a road base for the new interchange.

“We are taking the old Bangerter Highway, crushing it up and making it into a product to put into the new Bangerter Highway,” said Jake Nielson, contractor project manager on the Bangerter 4700 South project. “What most people don’t know is that most of the materials in our highways are 100 percent recyclable, whether that’s concrete or asphalt.”

Utah DOT noted that, for more than a decade, it has been working to eliminate stoplights on Bangerter Highway by converting intersections into interchanges.

As Bangerter Highway is one of the Salt Lake Valley’s largest north-to-south corridors – moving an average of 60,000 vehicles per day – removing stoplights and converting all intersections into freeway-style interchanges will enhance safety and help keep traffic moving in the ever-growing west side of the Salt Lake Valley.

State departments of transportation across the country are involved in a variety of material recycling and reuse efforts.

For example, the Idaho Transportation Department is engaged in a broad effort to develop environmentally-friendly solutions that reduce plastic waste from entering the natural environment; particularly where infrastructure projects are concerned.

For instance, the agency is now using biodegradable erosion control loose weave “blankets” without joints that allow snakes and other wildlife to easily move over or through them. Those “blankets” play a key role in the agency’s Erosion and Sediment Control or ESC practices that prevent soil loss and reduce sediment-laden stormwater runoff in and around transportation infrastructure.

In 2023, the New Jersey Department of Transportation released a video detailing how its use of “foamed glass aggregate” provides a multitude of green benefits to the state – especially as the material is made from recycled glass bottles.

The Illinois Department of Transportation began working with the Illinois Center for Transportation in December 2021 to develop more “sustainable pavement practices,” which includes ways to incorporate more recycled materials such as plastic into asphalt mixes.

Their joint project – dubbed “R27-196-HS: Rheology-Chemical Based Procedure to Evaluate Additives/Modifiers Used in Asphalt Binders for Performance Enhancements: Phase 2” – investigated methods to “soften” asphalt binder to reduce pavement cracking.

As recycled materials are added to hot mix asphalt, the asphalt tends to harden and become brittle, potentially leading to premature cracking. As a result, the project’s researchers began testing the use of different “modifiers” or softening additives to asphalt binders to improve long-term pavement performance, especially when recycled materials are used in the mix.

Meanwhile, the Pennsylvania Department of Transportation wrapped up a pilot project in 2021 that used pellets made from grocery bags, milk jugs, and other recyclable plastics in an asphalt reconstruction project.

Those pellets were added to the asphalt in two quarter-mile test sections of the project at the entrance to Ridley Creek State Park, about 15 miles west of Philadelphia.

Litter

Litter